According to recent data from the U.S. Environmental Protection Agency, this approach can reduce excavation time by up to 90%, significantly decreasing downtime and the associated hassles for businesses. Also, a survey by the American Society of Civil Engineers found that companies using trenchless methods saved up to 40% on repair costs and finished projects 30% faster. As today’s businesses demand smooth operations while addressing infrastructure needs, trenchless technology becomes an efficient solution. Let’s explore in detail about this technology and the benefits it can offer your business.

An Overview of Trenchless Technology

Unlike traditional methods that involve extensive excavation, trenchless techniques are minimally invasive solutions for installing, repairing, or replacing underground pipes and utilities that reduce surface disruption. This approach makes this technique ideal for commercial properties where maintaining daily operations and preserving aesthetic appeal are crucial. Essential trenchless methods used in commercial plumbing include:

- Horizontal Directional Drilling (HDD): This method involves drilling a horizontal borehole to install new pipelines or utilities.

- Pipe Bursting is ideal for replacing old, deteriorating pipes. This technique involves pulling a new pipe into place while breaking apart the old one.

- Sliplining: Involves inserting a smaller, new pipe into an existing pipe to restore its function or capacity.

Benefits of Trenchless Technology for Commercial Plumbing

Now that you have a clear idea of what exactly it is. Let’s further discuss the top benefits of trenchless technology:

-

Faster Repair and Installation Times

Trenchless technology offers a significant advantage over traditional methods by minimizing digging and surface disruption, leading to faster project completion. These methods typically require only a few hours to a day to complete repairs or installations. Drastically reducing the time needed compared to traditional methods, which can take several days or weeks to excavate.

-

Efficient for Difficult-to-Reach Areas

Unlike traditional methods that involve tearing up floors, walls, or sidewalks to access the damaged pipes, causing extensive damage and requiring costly repairs, trenchless technology is a versatile solution that allows repairs in these challenging locations without extensive digging or demolition.

-

Lower Long-Term Maintenance Costs

Using high-quality, durable materials reduces the frequency of future repairs and maintenance. Methods used, such as pipe relining, create a new, seamless pipe within the existing one that is resistant to corrosion and root intrusion.

-

Advanced Diagnostic Capabilities

Trenchless technology employs advanced diagnostic tools like video inspection cameras, which provide a clear view of the inside of pipes. This allows plumbers to accurately diagnose the problem before beginning any work. Precisely identifying issues ensures targeted repairs and reduces the chances of misdiagnosis and unnecessary repairs.

-

Reduced Need for Heavy Equipment

With trenchless technology, the need for heavy equipment often required for traditional excavation methods is significantly reduced. This lowers the cost and logistical challenges associated with heavy machinery and minimizes the risk of damaging existing infrastructure and landscapes.

-

Minimized Disruption to Business Operations

Traditional plumbing repairs often require extensive digging and excavation, which can interrupt daily activities, leading to downtime and lost revenue. In contrast, trenchless methods allow plumbers to repair or replace pipes with minimal digging, meaning businesses can continue operating with minimal disturbance.

-

Versatile Applications

Whether repairing damaged pipes, replacing old pipelines, or installing new ones, trenchless methods efficiently handle a wide range of situations. This adaptability makes them an excellent choice for different commercial properties, from small retail shops and large office complexes to industrial facilities.

-

Reduced Noise Pollution

Traditional plumbing repairs can be noisy and disruptive, causing disturbances to employees, customers, and nearby residents. Trenchless technology significantly reduces noise pollution by eliminating the need for heavy machinery and extensive excavation. Businesses and customers alike benefit from this quieter approach in commercial areas.

-

Adaptability to Different Pipe Materials and Sizes

Whether the pipes are made of clay, cast iron, PVC, or concrete, trenchless methods can effectively repair or replace them. This adaptability ensures businesses can benefit from trenchless technology regardless of their existing plumbing infrastructure.

Conclusion

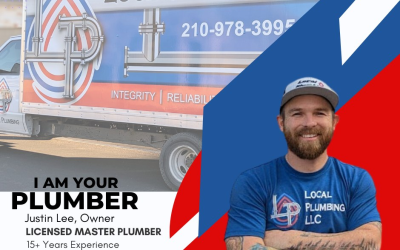

Why not enjoy the benefits of trenchless technology over traditional excavation methods for your commercial plumbing needs? Choose the expert from Local Plumbing LLC, with over 13 years of experience, to address your plumbing issues quickly. Whether you need services from plumbers in Schertz, plumbers in Cibolo, New Braunfels, & San Antonio, we are committed to delivering only quality work. Also, take advantage of our around-the-clock emergency services!